Heavy Duty Construction

Eloma ovens are manufactured with more, thicker stainless steel parts and less plastic parts. The weight of a Genius MT 20-21 is 495kg and market average is around 346kg.

1.2 mm thick stainless steel is used for the cooking chamber which is unique in the market where the average thickness is only 0.8mm.

Stainless steel used internally and externally: CrNi 18 10, BS 304 S 15, AISI 304.

Inverted Housings

Not just a hinge swap, Eloma left hand hinged units come standard with the controls on the right side of the oven meaning the user interface is always directly infront of the operator and opening the door will not impede operation.

Unique to Eloma ovens, this provides the best ergonomic solution and routing keeping technical needs at the accessible side at all times.

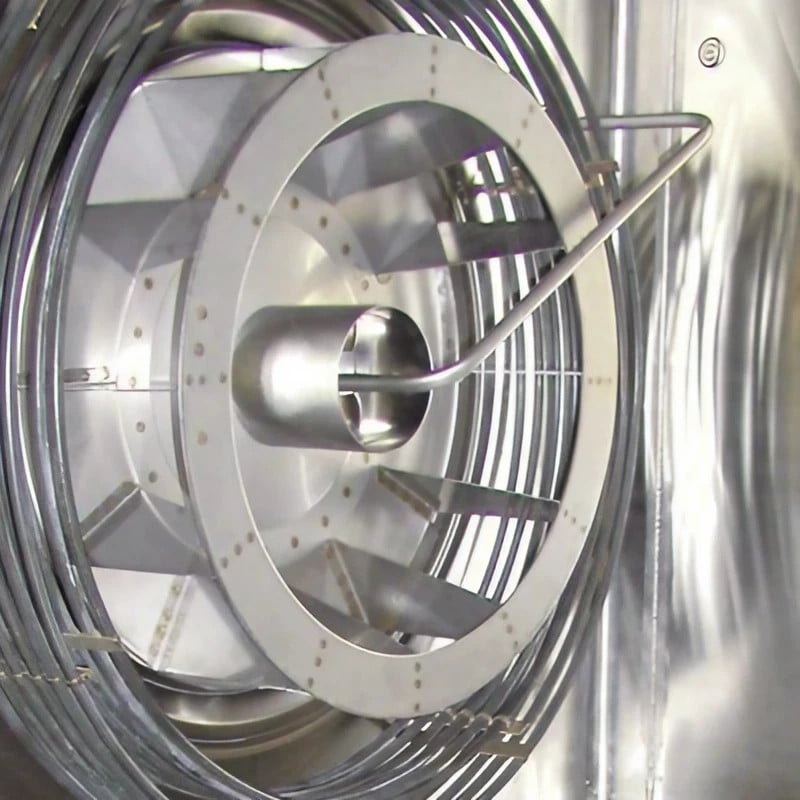

Live Steam System

Fresh steam is available within a matter of seconds without pre-heating allowing perfect steam saturation.

Economical and ecological with shorter cooking times, greatly reduced energy and water consumption.

Up to 42% less energy consumption compared to a boiler technology.

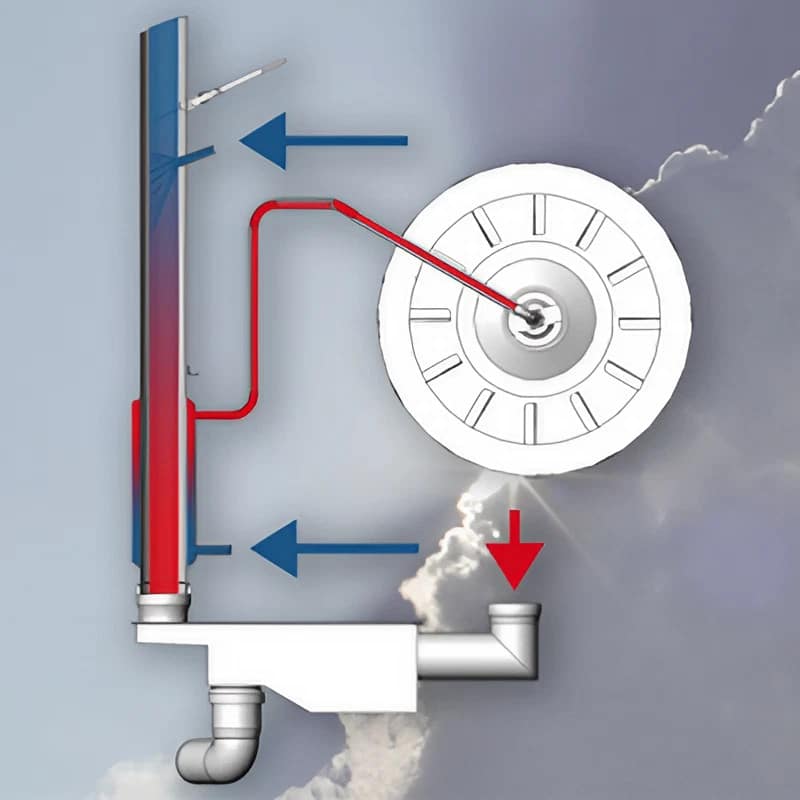

Multi-eco System

A high-performance heat exchanger allows savings of up to 16 % energy and up to 42 % water.

Eloma is the only manufacturer of combi steamers to date to have been awarded the Dr.-Georg-Triebe Innovation Prize in the category Ecology and Efficiency for its Multi-Eco System.

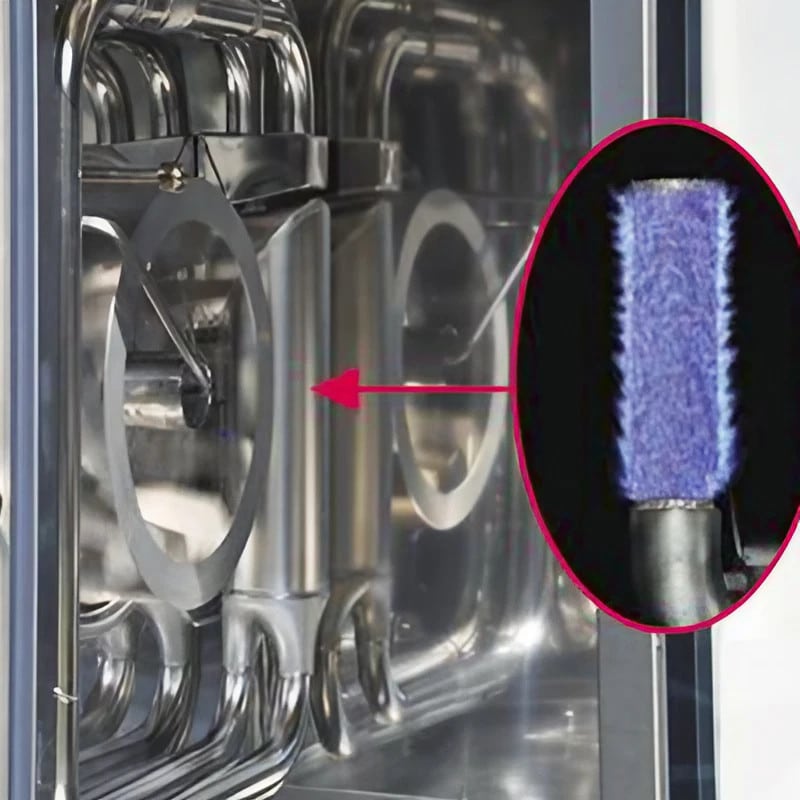

Reducing Emissions

Through highly efficient gas technology with a triple pipe heat exchanger Eloma ovens have over 87% efficiency compared to the market average of around 70%.